We use the Pallet Design System™ (PDS) software that was created by Virginia Tech to standardise design and technical procedures that determine the structural adequacy and expected performance of wooden pallets.

We have ten trained PDS designers, whose experience and competence with the system, combined with their extensive product knowledge and understanding of the context of use, supports our customers by managing the balance between what is fit for purpose and safe, with the most commercially viable option.

The Pallet Design System™, or PDS software, was developed by the Pallet Laboratory on the campus of Virginia Tech. It was first launched in 1980 as a result of an extensive research project that had the goal of developing pallet design standards which could provide pallet users a necessary means of communication with pallet manufacturers for defining expected performance.

The research and development effort which led to the first version of PDS has continued ever since. Each new version of PDS incorporates the latest data, engineering and technologies. At version 5.1, the 33rd version of PDS, NWPCA promises that PDS will remain, first and foremost, the premier design tool for wooden pallets.

| Pallet Type | Dimensions | Load Bearing* |

|---|---|---|

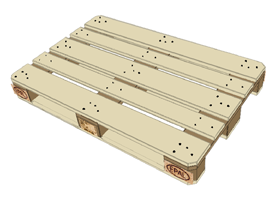

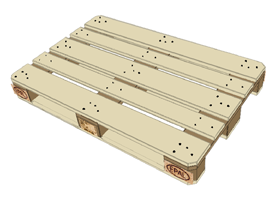

| EPAL – licensed Euro | 800 x 1200mm | 2500kg |

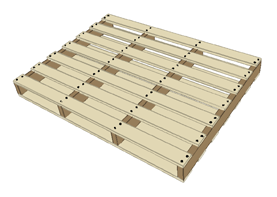

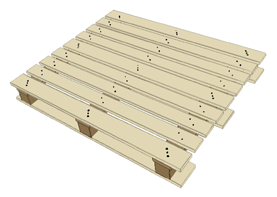

| 4 way perimeter base | 1200 x 1000mm | 1200kg |

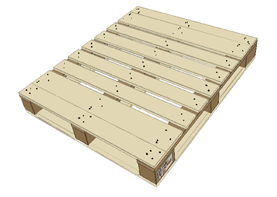

| 2 way reversible | 1000 x 1200mm | 1200kg |

| 4 way non perimeter base | 800 x 600mm | 600kg |

*stacked one unit load high

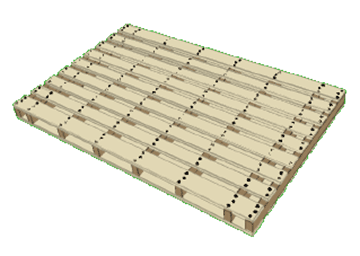

Our team will work alongside you to fully understand your requirements. Using our PDS software, combined with our product knowledge and design experience, we will offer you a range of options that fulfil your commercial, logistical, sustainability and safety requirements.

We have well invested automated production facilities for the manufacture of our new timber pallets, as well as specialist bench made, bespoke pallets for diverse range of industries.

From our standard range of products, to fully bespoke, sustainable pallet solutions, all manufactured goods supplied are documented in the form of a technical drawing which supports our quality management system and ensures compliance with specification.

Our standard range of products includes 2-way, 4-way, ISPM15, kiln-dried and CP pallets. We are also licensed to produce and repair EPAL Euro pallets.

Products are available as FSC® certified (FSC-C041490) upon request only.

A 2-way entry pallet is one that can be accessed from two of its four sides.

A 4-way entry pallet is one that can be accessed from all four of its sides.

An accredited process of heat treatment achieved within a kiln, to meet phytosanitary export requirements.

We operate a TIMCON accredited process of kiln drying timber to meet agreed moisture content levels, which deliver added product protection.

The standard European pallet as specified and licenced for manufacture by the European Pallet Association (EPAL).

A range of licenced specifications predominantly used within the chemical sector.

Designed and manufactured to your specific requirements with consideration to pallet application and safe working loads.