Market Trends

Followers of industry reports, commentaries and this regular Market Update, will have seen that the challenges we have been reporting in recent times remain with us. In fact, some of our industry challenges have become more acute at the time of writing. For the most part, the global economy’s post-Covid emergence from lockdown and the varying recovery rate across continents has tested the resilience of supply chains beyond capacity.

Whilst significant challenges remain within the timber market, our recent experience has seen some supply lines moving more freely. This has yet to translate into any softening of price, but it may at least signal some welcome stability as we enter 2022. Conditions may also be helped during the coming months, as typically there is some seasonal relief in key sectors like construction. Furthermore, the construction sector is simultaneously experiencing an unwelcome recovery drag, with extended raw material lead times, site labour, and haulage shortages suppressing demand. Some clients have even deferred project start dates until stability emerges.

We are also experiencing pallet supply constraints in the reconditioned market. We are entering Q4 where seasonally, we typically experience an increase in demand, but there remains a severe shortage of used pallets coming back into circulation. This may be due to a combination of factors such as recycling pallets instead of reusing them, together with strong competing demand for reconditioned pallets in the EU.

Our national network of reconditioned pallet sites is therefore inviting businesses to engage with our pallet buying team to identify an opportunity to offset rising costs by selling unwanted pallets to us, anywhere in the UK.

To arrange a collection or find out more email: palletcollection@scott-pallets.com

Positively, the resilience of Scott Group’s supply chain and our successful partnerships with the largest mills in the UK and the Baltics have allowed us to maintain continuity of service for our customers. Shipping availability has been a particular challenge for our Baltic supply line, and this prompted us to take a decisive step in exclusively chartering what is possibly the largest vessel dedicated to pallet wood ever to arrive in UK waters! Featured below, the 118m “Norrland” vessel arrived with 6,678m3 of sustainably sourced timber.

Watch our video of Norrland here.

European, monthly and quarterly timber price movements are well documented in several respected, independent indices, including the FEFPEB Pallet Timber Price Index covering UK, Germany, Netherlands, Italy and Sweden; the German HPE; French CEEB and UK Afry indices (all available either online or from your account manager, who will gladly talk through any concerns you may have).

Investment in new automation

We continue to re-invest in the business to ensure we stay at the forefront of productivity and service.

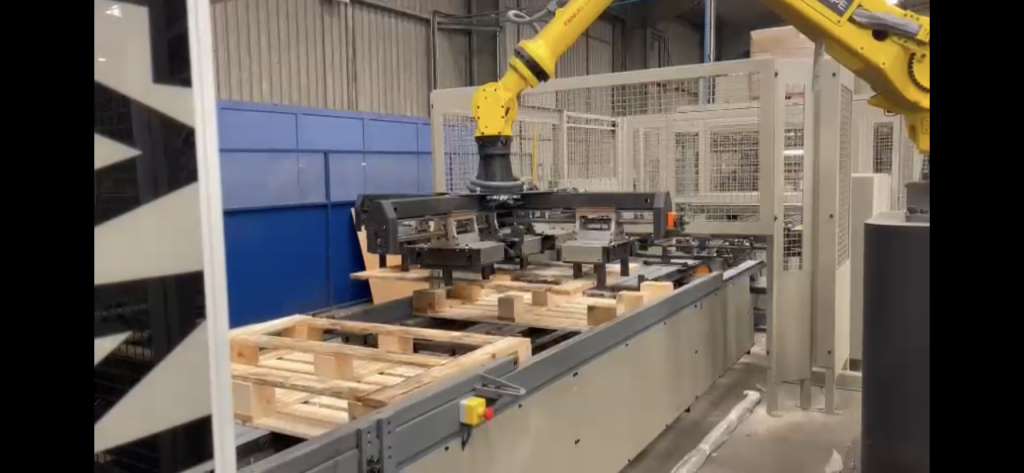

In our manufactured pallet business unit, we’ve just completed the installation of a state-of-the-art Cape Tandem machine at our Barry site.

The £1.5m investment will not only improve productivity and quality but also adds to our manufacturing capacity with the ability to produce more than 300 pallets per hour.

The equipment increases our automated capabilities with robotic functionality replacing manual human handling – not only reducing risk but freeing up our personnel to support in different areas of production to continue improving our service.

COP26

Many will be aware of the increased focus on COP26, taking place from 1-12 November in Glasgow, formally hosted under the UK Presidency.

COP26 is the 26th meeting of the Conference of Parties, essentially the 26th year that governments, trade unions, businesses, and everyone else with an interest in climate change meets to review and negotiate global action. Six years from the 2015 Paris Agreement, it’s seen as a key moment to take stock of progress and ramp up commitments alongside a clear plan of action for how climate action targets will be met in the short, medium, and long term.

Sustainability is integral to our core business values, and it shapes the way we work across our operations in the UK and how we engage with our global supply chains. We aim to minimise the environmental impact of our products at each stage of their life cycle. We look to deliver innovative and sustainable solutions and services to our customers who promote circular economy principles, aiming for zero non-recovered waste. By recycling our internal waste in all of our facilities, we also avoid generating landfill waste.

As outlined earlier, market pressure is driving timber pallet prices up and creating significant challenges for timber availability. A growing desire and drive to source sustainable packaging solutions are evident across all parts of the UK construction supply chain. Businesses are looking for innovative ways to operate following circular economy principles, which protect the environment.

Environmentally and commercially, there has never been a better time to consider pallet reuse as a central element in any sustainable procurement strategy. Scott Pallets’ award-winning recovery, repair and reuse service has supported UK industries, including construction product manufacturers, housebuilders and merchants, to reuse pallets for more than ten years.

We currently work with at least 2,000 construction site collection points across the whole of the UK. Recovering pallets for repair and reuse by UK’s leading construction product manufacturers. We’re playing our part in eliminating all forms of avoidable waste by 2050.

View the Scott Pallets Recovery brochure

As the UK’s leading pallet solutions provider, you can be confident that we are working hard to support your business to navigate through whatever challenges the supply chain presents.