Following the launch of our new £1.5m Cape tandem pallet machine at our Barry site last year, we’re continuing to invest and upgrade our manufacturing and reconditioned sites around the country.

At Ellesmere Port, our 3000m² yard extension has just been completed. The new and improved yard is ensuring we make best use of the space available, improving the layout from both an operational and health and safety perspective, and providing us with increased capacity for pallet storage.

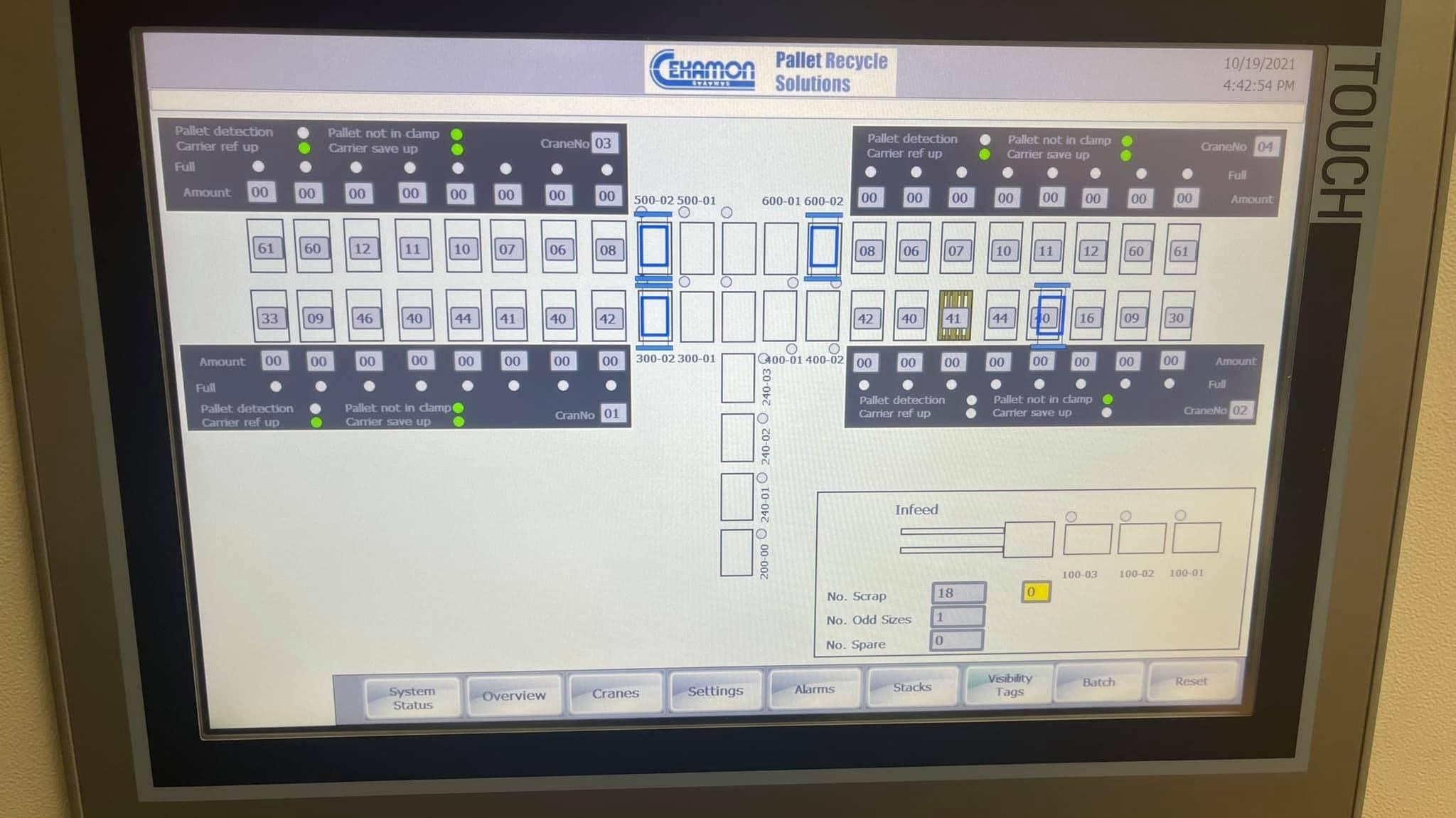

Our new Cekamon sorting machine at the Bathgate site is now fully operational. With four overhead cranes, this new equipment enables the automatic sorting of up 32 different types of pallets to help drive up efficiency for the reconditioned business.

This incredible machine really revolutionises our pallet sorting capabilities and has the capacity to sort on average 400 pallets per hour – that’s twice the speed of hand sorting. This frees up valuable manpower for our increasing volume of pallet repair jobs.

In response to the increased demand for heat-treated pallets as a result of Brexit, we’ve also been adding to our kiln capacity throughout our nationwide network of pallet manufacturing sites. In March we installed a new kiln at Derby, and our most recently commissioned new kiln is at our Rotherham site. This PES Bowman kiln has the capacity to heat-treat 15,000 pallets per week.

We’re now in the process of planning another four new kilns sites and will report back soon.